Machine categories at a glance

Whether it’s making crooked things straight again or assemble components, with our special machine tools we always have the right solution for you. Here you will find all information about our manual straightening presses, our automatic straightening machines, our wheelset assembly presses and much more.

On this page:

Manual straightening presses

The deformation of metal workpieces is an undesired, yet material inherent consequence of various metal working and refining processes. It requires a sophisticated straightening process to bring the parts back into their ideally designed shape so that these high-quality components can perfectly and durably fulfil their intended tasks.

MAE manual straightening presses offer a cost-effective concept, guaranteeing precise and sensitive processing of your workpieces. Measuring in one setting ensures high repeating accuracy and fast working even for less experienced operators.

General properties

Pressing forces from 160 to 20,000 kN

Workpiece lengths from 30 to 20,000 mm

Workpiece diameters from 3 to 900 mm

Unit weights from 5 grams to 20 tons

Straightening accuracy down to 0.01 mm

Automatic straightening machines

Are you straightening short or long parts, round or profiled? Are you looking for the right machine for your straightening process?

We have two concepts: our automatic straighteners of the M-AH and ASV series.

With these series, you straighten your workpieces efficiently and precisely down to 0.01 mm.

General properties

Pressing forces from 15 to 25,000 kN

Workpiece lengths from 40 mm to 30 m

Workpiece diameters from 2 to 800 mm Unit weights from 5 grams to 20 tons Straightening accuracy down to 0.01 mm

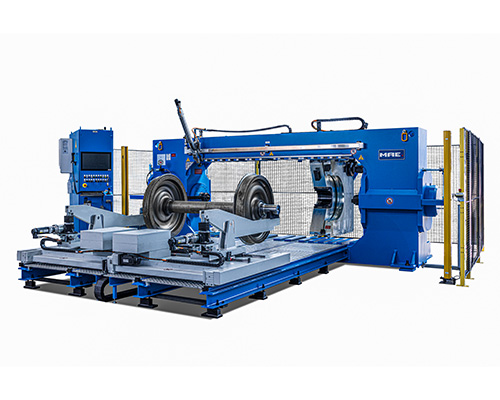

Wheelset presses

Innovative technical solutions. For more than 70 years, MAE![]() has been developing and supplying assembly presses for rail vehicle wheelsets. Whether high-speed trains or street cars, we have the right solution.

has been developing and supplying assembly presses for rail vehicle wheelsets. Whether high-speed trains or street cars, we have the right solution.

General properties

Pressing forces from 2,000 to 6,300 kN

Shaft lengths from 400 to 3,200 mm

Wheel diameters from 400 to 1,500 mm

Unit weights up to 8,000 kg