Workpieces & Applications

You do not yet know exactly which machine concept is the right one to solve your problem? No problem at all!

Here you will find a variety of different workpieces for which we already have a solution. Maybe your workpiece type is already included.

We will be happy to recommend the right machine concept for you.

On this page:

Shafts

Shafts are the most common parts to be straightened. Special shafts, such as engine and transmission shafts for automotive construction and large engines, put special demands on the straightening process.

Here, too, MAE![]() offers individual solutions. Standard shafts are usually straightened quickly and precisely on our automatic straightening machines of the M-AH series in reliable processes using the bend-straightening method. If forces of more than 1,600 kN are required, one of our ASV series straightening machines is your first choice.

offers individual solutions. Standard shafts are usually straightened quickly and precisely on our automatic straightening machines of the M-AH series in reliable processes using the bend-straightening method. If forces of more than 1,600 kN are required, one of our ASV series straightening machines is your first choice.

With the right MAE machine...

machine...

- you straighten very accurately! For example, long, slim ball screws for textile machines that run at particularly high speeds, or steering racks with asymmetrical cross-sections that tolerate no compromises in accuracy.

- you avoid cracks consistently!

Slim, often hollow parts with special cross-sections and offsets in the cross-sections are sensitive. For these parts, pressure-straightening is the process of choice. - you measure gear teeth exactly!

Important for all shafts that transmit torque.

Questions about shafts?

Please contact us for this purpose:

Tools / Standard Parts

Also for special materials:

Tools such as drills and deep hole drills are directed relative to the clamping shank. These parts are usually particularly slim and almost without exception must have special accuracies.

With the right MAE machine...

machine...

- you straighten the whole range! Drills with diameters from 6 to 42 mm and with lengths from 140 to 1,800 mm are automatically straightened on our straightening machines of the M-AH series and manually on our straightening presses of the S RH series.

- you straighten special materials!

Drill pipes, as used in the oil and gas industry, are long, slim parts made of tough materials such as high-strength steels. Due to their length, our ASV is used here for automatic and our P-H RH or S RH for manual straightening processes.

Questions about tools and standard parts?

Please contact us for this purpose:

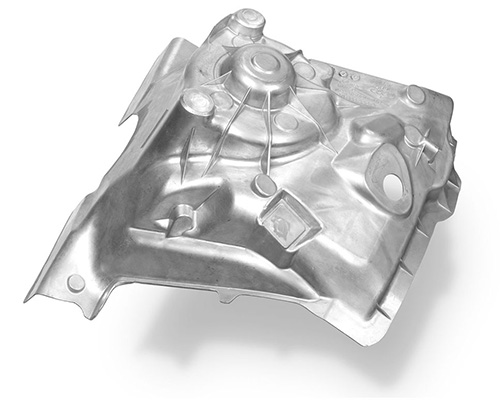

Cast / forged parts

Straightening in all three dimensions:

Cast and forged parts are used in a variety of applications: in automotive engineering, large engines for the energy industry or as wheelset shafts for rail vehicles.

Often these parts are irregularly shaped and are straightened in a particularly harsh environment. In order to still achieve accurate straightening results, there are MAE![]() solutions.

solutions.

With the right MAE machine...

machine...

- you straighten accurately in harsh environments!

Blanks of shafts, gears or engine parts and wheelset shafts for rail vehicles are straightened automatically on our M-AH or ASV series machines or manually on our S RH series presses, depending on force requirements and length. - you straighten exactly in three dimensions!

Castings for chassis or structural parts are filigree, have particularly tight tolerances and require different directions of action. Here we offer our automatic straightening machines of the M-ASRU series as a standard concept for special solutions.

Questions about cast or forged parts?

Please contact us for this purpose:

Profiles and semi-finished products

Smallest tolerances and lengths up to 30 m: Profiles and semi-finished products often pass through a MAE![]() straightening line twice during their manufacturing process: first as semi-finished products and after application-specific cutting to length.

straightening line twice during their manufacturing process: first as semi-finished products and after application-specific cutting to length.

With the right MAE machine...

machine...

- you straighten particularly accurately!

The tolerances of guide rails and racks are often in the range of hundredths of a millimeter. For parts up to a length of 3 m, our M-AH for automatic and our S RH for manual straightening processes are the right equipment. - you straighten accurately, even in harsh environments!

For example, rails, rolled sections, round or flat steels in rolling mills. - you straighten lengths up to 30 m!

Even large profiles with a non-round cross-section, with dimensions up to 1,200 mm x 500 mm are best straightened on our ASV series automatic straightening machine.

Questions about profiles and semi-finished products?

Please contact us for this purpose:

Tubes

For thin wall thicknesses and long lengths:

When straightening pipes, there is a special challenge to consider, which arises for one simple reason: every pipe is hollow! Damage or even collapse of the pipes can be reliably prevented, especially with a lot of experience!

With the right MAE machine...

machine...

- you straighten without collapsing!

Only one thing can help here: comprehensive experience in the design and use of the straightening tools. - you straighten particularly precisely!

To meet automotive requirements, camshaft tubes or tubes used as drive shafts for rear wheels are gladly straightened automatically on our M-AH or manually on our S RH. - you straighten long lengths!

Oilfield tubes up to 20 m are particularly straight when automatically straightened on an ASV. - you straighten especially thin-walled tubes!

Pipeline pipes with diameters of up to 1,200 mm often have very small wall thicknesses. Our ASV is also ideally suited for them. - you straighten tough materials and large wall thicknesses!

Pipes used in power plants are made of high-strength steels. Particularly high straightening forces are required here. Our ASV achieves this effortlessly.

Questions about tubes?

Please contact us for this purpose:

Welded parts

Standard concepts for special solutions:

Welded usually also means distorted: The deformation results from the heat input during welding. Furthermore, the weld seam itself is delicate and breaks easily.

With the right MAE machine...

machine...

- you straighten complex structures! Jointed shift forks or chassis parts often have to be clamped at predefined spatial points and straightened in different spatial directions. Here, with our automatic straightening machines of the M-ASRU series, we offer a standard concept also for special solutions.

Questions about welded parts?

Please contact us for this purpose:

Wheelsets

According to country-specific standards:

Pressing wheelsets means precisely positioning components with a large mass and handling them efficiently in line with the application. In MAE![]() wheelset presses, the tools are designed to minimize the installation space. We also offer a variety of solutions for efficiently loading and unloading the unwieldy wheelsets.

wheelset presses, the tools are designed to minimize the installation space. We also offer a variety of solutions for efficiently loading and unloading the unwieldy wheelsets.

With the right MAE machine...

machine...

- you press all wheelset elements!

Wheelsets with and without brake disc, drive wheel sets for railcars, wheel sets for locomotives with gearbox and/or with traction motor. - you document the process comprehensively!

Including the force-patch course and geometry characteristics. - you comply with the different standards worldwide!

Whether DB, GOST, AAR or TBT – all common country-specific standards are taken into account in the RACOS wheelset press control system.

Questions about wheelsets?

Please contact us for this purpose:

Have you already had an insight?

Have you already taken a look at our manual and automatic straightening machines?

Or have you had a chance to look at the different processes?